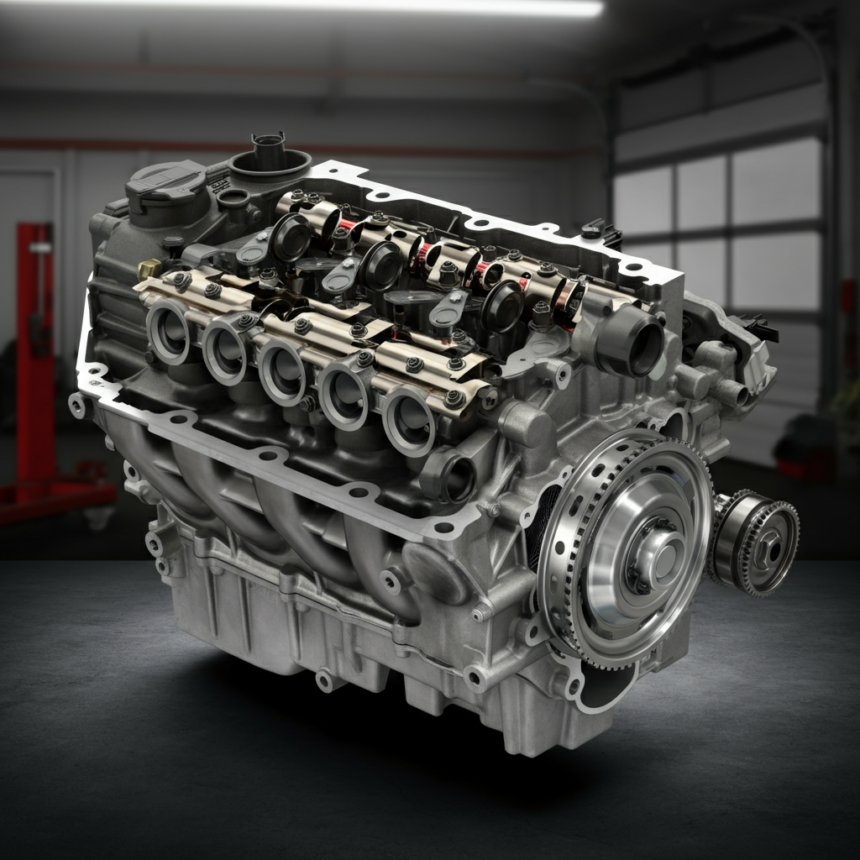

When it comes to maintaining the performance and longevity of an Audi 5 Cylinder 10v Turbo Valve Shims understanding the nuances of valve shims is an absolute must. For many Audi enthusiasts and DIY mechanics, these small but impactful components play a vital role in ensuring optimal engine operation.

This guide is tailored to help you explore everything there is to know about Audi 5 Cylinder 10v Turbo valve shims. From understanding their function to learning how to adjust them, we’ll equip you with the knowledge you need to keep your engine running smoothly.

What Are Valve Shims in the Audi 5 Cylinder 10v Turbo Valve Shims?

Valve shims may be tiny in size, but their role in engine performance is enormous. They are small discs (typically made of durable steel or other metal alloys) that sit between the camshaft and the valve lifter. These shims serve a critical purpose in maintaining proper valve clearance—the space between the camshaft and the valve.

Why is Valve Clearance Important?

Proper valve clearance ensures the valve timing is accurate, allowing valves to open and close at the right times. Incorrect valve clearances can result in poor engine performance, excessive wear on engine parts, and even internal damage in extreme cases.

The Audi 5 Cylinder 10v Turbo’s unique design makes valve shim maintenance particularly crucial. Its powerful yet compact layout often subjects components to high stress, making regular checks and adjustments essential.

Understanding Valve Shims: Function and Importance

Valve shims function as spacers to fine-tune the clearance between the camshaft lobe and the valve lifter. Here’s why they matter:

- Efficiency: Optimal valve clearance maximizes engine efficiency by ensuring the fuel-air mixture enters and exhaust gases exit the cylinder smoothly.

- Prevents Noise: When valve clearance is either too loose or too tight, it can lead to distracting ticking noises or misfiring.

- Longevity: Proper valve clearance reduces wear and tear on both the camshaft lobes and valves, extending the engine’s lifespan.

Failure to maintain the right clearance could lead to severe engine issues, including loss of compression and damaged valves. For enthusiasts who want to keep their Audi 5-cylinder engine performing at its peak, this is a non-negotiable part of vehicle maintenance.

Tools and Materials Needed for Valve Shim Adjustment

Before you get started, make sure to gather all the necessary tools and materials. Adjusting valve shims requires precision, so having the right equipment is key.

Tools:

- Feeler Gauge – To measure valve clearances precisely.

- Torque Wrench – For tightening bolts to the recommended specifications.

- Valve Adjustment Tool – A specialized tool designed to make shim removal and installation easier.

- Camshaft Timing Tool – To maintain correct camshaft alignment.

- Micrometer – For measuring the thickness of valve shims.

Materials:

- Replacement valve shims of various thicknesses.

- High-quality engine oil.

- Cleaning cloths and degreasers to remove dirt and debris.

Having these essentials on hand will save you time and ensure accuracy during the adjustment process.

Step-by-Step Guide to Checking and Adjusting Valve Shims

Step 1: Prepare Your Work Area

Ensure that the engine is cool and your workspace is clean and well-lit. Disconnect the battery for safety.

Step 2: Remove Engine Components

Carefully remove components like the valve cover and timing belt to access the camshaft and valves. Keep all parts organized to ensure proper reassembly.

Step 3: Measure Valve Clearance

Using a feeler gauge, measure the clearance between the camshaft lobe and the valve lifter. Refer to the Audi 5 Cylinder 10v Turbo service manual for the recommended specifications.

Step 4: Determine Necessary Adjustments

If the clearance is outside the manufacturer’s specifications, calculate the shim thickness needed to correct the clearance. This involves subtracting or adding the difference from the current shim thickness.

Step 5: Replace Valve Shims

Using the valve adjustment tool, remove the old shim and insert the new one. Double-check the thickness with a micrometer to ensure accuracy.

Step 6: Recheck Clearances

After replacing the shim, use the feeler gauge again to confirm the valve clearance is within the correct range.

Step 7: Reassemble

Once all valves are properly adjusted, reattach the engine components, ensuring bolts are torqued to the manufacturer’s recommendations.

Common Issues and Troubleshooting

Even with careful attention, you may encounter challenges. Here are some common issues and troubleshooting tips:

- Incorrect Measurements

Double-check measurements with a micrometer and feeler gauge. Even a slight miscalculation can cause significant performance issues.

- Damaged Shims

Inspect shims for signs of wear or breakage. Replace any that appear damaged, even if they meet thickness requirements.

- Persistent Noise

If ticking noises persist after adjustment, it could indicate an unrelated problem with the camshaft or lifters. Inspect these components and consult a professional if needed.

Tips for Maintaining Optimal Valve Clearance

- Follow Service Intervals

Regularly check and adjust valve shims as part of your Audi’s recommended maintenance schedule.

- Use High-Quality Parts

Always opt for OEM or high-quality aftermarket valve shims. Inferior parts can wear out quickly, causing more frequent adjustments.

- Listen to Your Engine

Pay attention to unusual noises, as they often indicate valve clearance issues. Early detection can prevent major repairs down the line.

- Seek Expert Advice

If you’re unsure about any aspect of valve adjustment, consider consulting a professional mechanic familiar with Audi engines.

Why Regular Valve Maintenance is Non-Negotiable

Proper valve clearance is critical for keeping your Audi 5 Cylinder 10v Turbo running at peak performance. Neglecting this maintenance task can lead to a host of problems, including reduced efficiency, increased emissions, and potential engine failure.

By understanding the function of valve shims, investing in the right tools, and following the correct procedures, you can ensure your engine remains in excellent condition for years to come. And remember, preventive maintenance is always less expensive than major repairs!

FAQs

How often should valve clearances be checked on an Audi 5 Cylinder 10v Turbo?

Generally, valve clearances should be inspected during regular maintenance, every 30,000–50,000 miles, or as recommended in your vehicle’s manual.

Can I adjust valve shims myself, or should I see a mechanic?

While adjusting valve shims is doable for experienced DIY mechanics, it requires precision and specialized tools. If you’re new to engine maintenance, consulting a professional is advised.

What are the signs of incorrect valve clearances?

Common symptoms include engine noise (such as ticking), reduced performance, misfiring, or difficulty starting the vehicle.

Does cold weather affect valve clearance?

Yes. Valve clearances tend to shrink slightly in cold temperatures due to metal contraction. This is why adjustments are typically made when the engine is cool.